The role of steel shot in industrial production

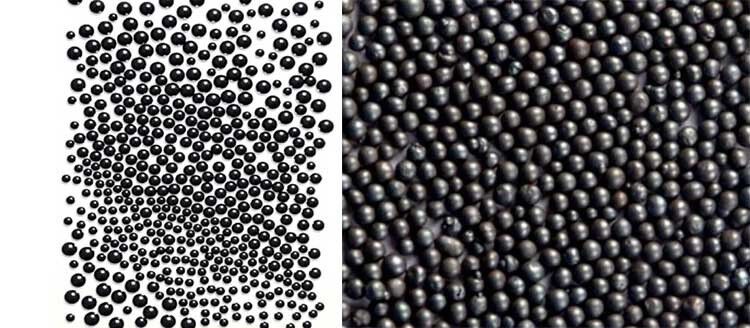

Steel shot is a spherical particle made from a special material that has undergone special heat treatment. It is widely used for shot peening of large quantities, heavy-duty parts or materials. What are the roles of steel balls in industrial production?

In large-scale steel structure projects such as shipbuilding and bridge construction, due to the long construction time, a steel plate pretreatment assembly line is set up to prevent rusting of the steel during the construction process. High automation rust removal and pre coating of workshop primer are carried out.

The main consumable for shot blasting and rust removal in the pre qualification of steel is steel shot

The main methods for rust removal of steel are shot blasting and shot blasting. Shot blasting uses a rotating impeller to throw steel balls towards the workpiece, forming high-speed impact rust removal. Shot blasting uses compressed air to spray steel balls onto the workpiece to remove rust. Anyway, the main body of action is steel shot, so the industrial production demand and consumption of steel shot are huge.

Steel shot is a high-quality wear-resistant material. The steel shot has moderate hardness, good impact resistance, and long service life. Steel shot is widely used in many fields, such as castings, forgings, machined parts, and heat-treated parts.

In large-scale steel structure projects such as shipbuilding and bridge construction, due to the long construction time, a steel plate pretreatment assembly line is set up to prevent rusting of the steel during the construction process. High automation rust removal and pre coating of workshop primer are carried out.

The main consumable for shot blasting and rust removal in the pre qualification of steel is steel shot

The main methods for rust removal of steel are shot blasting and shot blasting. Shot blasting uses a rotating impeller to throw steel balls towards the workpiece, forming high-speed impact rust removal. Shot blasting uses compressed air to spray steel balls onto the workpiece to remove rust. Anyway, the main body of action is steel shot, so the industrial production demand and consumption of steel shot are huge.

Steel shot is a high-quality wear-resistant material. The steel shot has moderate hardness, good impact resistance, and long service life. Steel shot is widely used in many fields, such as castings, forgings, machined parts, and heat-treated parts.

The above is the role of steel shot in industrial production, which can be used as a reference when in use. Used for secondary treatment after steel shot to remove iron contamination and reduce surface roughness of parts.

Editor: Nancy

steel shot Relevant information

steel shot Related Products

- E-mail zs@sdsmachinery.com

- whatsapp +8615653328535

- Wechat +8615965331535

-

Shandong Metal Abrasive Co., Ltd produces China steel shot and alloy steel shot at a low price, with a complete range of models and a professional team