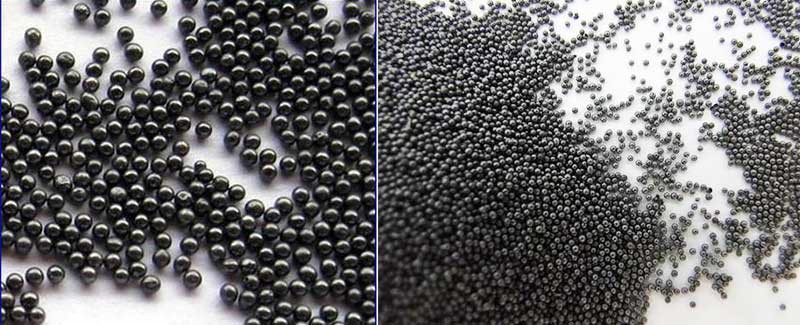

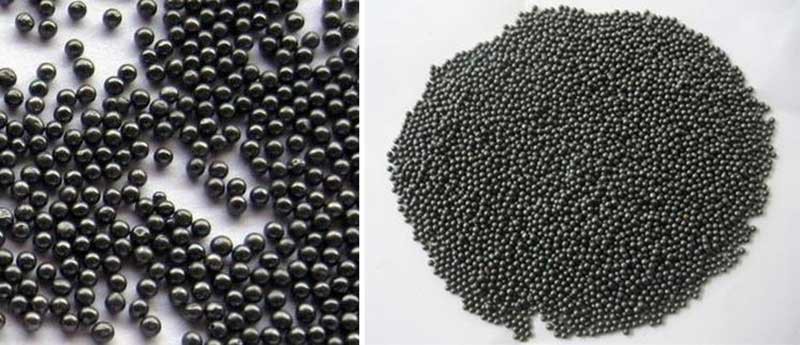

Cast steel shot

- Product name : Cast steel shot

- Product Categories : Cast steel shot

- Manufacturer/Supplier: Shandong Metal Abrasive Co., Ltd

Cast steel pellets are made from high-quality steel shavings, which are first melted and then formed into small spherical shapes using high-pressure water jetting. The formed pellets are heated again to purify the homogeneity, and then subjected to quenching treatment. The quenched pellets are dried in the furnace and reheated for tempering to achieve the appropriate hardness. The tempered steel pellets are sorted into 11 grades that meet SAE standards through mechanical screening for use in shot blasting equipment. Products with different particle sizes and hardness are used for different processes, such as surface strengthening.

Cast steel shot is widely used for descaling and rust removal of steel workpieces before coating, in which centrifugal shot blasting equipment is often used. The spherical shape and lower hardness will prevent the steel shot from causing significant wear on the equipment. Steel balls are also widely used in the casting industry. After the workpiece is removed from the mold, use steel balls to remove the sand on the surface of the workpiece. When steel shot is used with suitable equipment, it is definitely the abrasive for surface cleaning due to its durability.

Related Products

- E-mail zs@sdsmachinery.com

- whatsapp +8615653328535

- Wechat +8615965331535

-

Shandong Metal Abrasive Co., Ltd produces China steel shot and alloy steel shot at a low price, with a complete range of models and a professional team