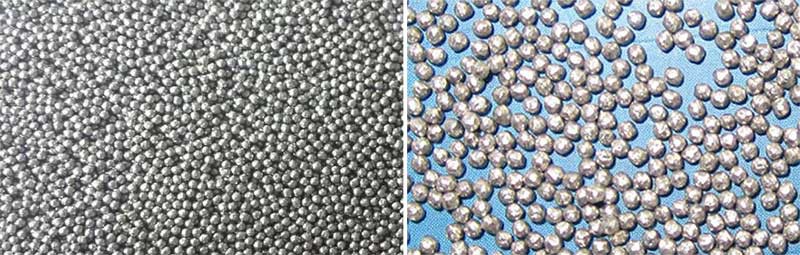

Stainless Steel Shot

- Product name : Stainless Steel Shot

- Product Categories : Stainless Steel Shot

- Manufacturer/Supplier: Shandong Metal Abrasive Co., Ltd

Stainless steel shot, also known as stainless steel shot or stainless steel wire cutting shot, is a particle that accepts the cutting habits of stainless steel wire. Stainless steel shot manufacturers are mainly used for the appearance shot blasting, sandblasting, shot blasting treatment, shot blasting forming, finishing, matte, proofreading, paint stripping, and erosion removal of stainless steel parts, aluminum alloy die-casting parts, and copper alloy parts. It is refined by processes such as wire drawing, cutting, and rounding, with a bright and rust free appearance, spherical shape (cutting shot, cylindrical shape), and better wear resistance than general forged steel shot on the market.

Stainless steel shot is widely used in various industries such as non-ferrous metal castings, stainless steel products, aluminum profiles, hardware objects, and natural stone for appearance shot blasting. Stainless steel shot manufacturers use sandblasting, shot blasting forming, finishing, strengthening, matte, proofreading, paint stripping, and erosion removal to highlight the essence of the metal, making the metal appearance bright, rust free, and achieving matte results. Its wear resistance is better than that of general forged steel shot in the market.

From a metallographic perspective, stainless steel contains chromium, which results in a very thin chromium film on its surface. This film separates and resists the invasion of oxygen into the steel, providing the advantage of corrosion resistance. In order to maintain the inherent corrosion resistance of stainless steel, it contains over 12% chromium.

Stainless steel is very suitable for hospitals or other platforms where hygiene conditions are crucial, especially for stainless steel that has undergone secondary processing and polishing, resulting in better results. The reason why stainless steel ball manufacturers usually request a smooth appearance in terms of erosion is because the appearance is smooth and not prone to scaling. The deposition of dirt can cause stainless steel to rust and even lead to erosion.

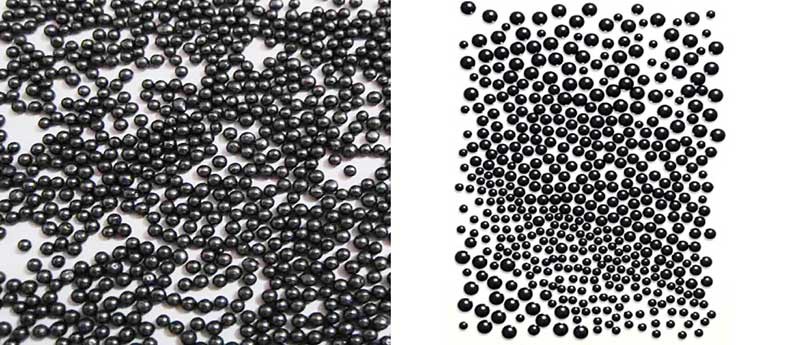

Related Products

- E-mail zs@sdsmachinery.com

- whatsapp +8615653328535

- Wechat +8615965331535

-

Shandong Metal Abrasive Co., Ltd produces China steel shot and alloy steel shot at a low price, with a complete range of models and a professional team