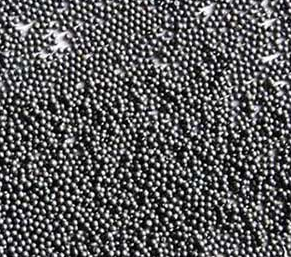

How to check the quality of steel shot

Steel balls are made from scrap steel. Firstly, it is melted, then the molten steel is made into small balls by high-pressure water injection, and the formed balls are reheated for purification and homogenization, followed by quenching. The quenched pellets are dried in the furnace, then heated and tempered to achieve the appropriate hardness. According to the standards of the American Society of Automotive Engineers, tempered steel shot is mechanically screened into 11 grades by shot blasting equipment.

1. Hardness testing

Generally, microhardness testers are used for testing, and different standards have different requirements for the hardness of steel balls. Hardness is more important in the strengthening process.

2. Shape detection

Usually a 25x magnifying glass is used, but now there are various USB interface magnifying glasses that can be directly connected to a computer, making it more convenient to use.

3. Dimensional inspection

Usually, a vibrating screen is used for detection, and the selection of different standard sieves may vary slightly.

4. Visual inspection

By visual inspection, check whether the surface of the steel shot is clean.

5. Detection of fragmentation rate and service life

This requires testing through specific equipment (Owen detector), which is generally not convenient for testing in this factory and is mainly provided by abrasive suppliers.

Steel shot is mainly used for surface shot blasting, sandblasting, shot blasting treatment, shot blasting forming, finishing, strengthening, matte, correction, paint stripping, and corrosion removal of stainless steel parts, aluminum alloy die-casting parts, and copper alloy parts.

Editor: Lena

Next: 合金鋼丸提高質(zhì)量的途徑

steel shot Relevant information

steel shot Related Products

- E-mail zs@sdsmachinery.com

- whatsapp +8615653328535

- Wechat +8615965331535

-

Shandong Metal Abrasive Co., Ltd produces China steel shot and alloy steel shot at a low price, with a complete range of models and a professional team