Will water vapor affect the quality of steel shot casting?

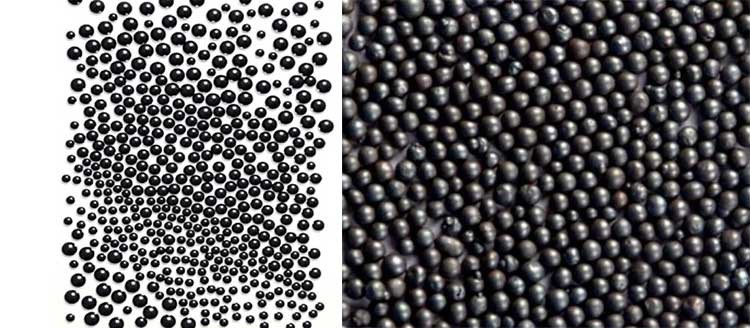

During the casting process of steel shot, some factors can seriously affect the production quality and effectiveness of the equipment, and need to be avoided in a timely manner. Water vapor is one of the serious influencing factors. Water vapor exists in a gas-liquid state. During product production, some applications operate in environments with high temperatures, leading to the occurrence of water vapor. Over time, all products will be oxidized, which will affect the use of the equipment. So, let's briefly understand the impact of water vapor on the quality of steel shot casting.

1. Due to the fact that substances rich in water vapor can dissolve in oxide crystals, the oxidation kinetics will be affected when water vapor appears.

2. When steel balls are rich in water vapor, water vapor accelerates high-temperature oxidation.

3. Water vapor is still one of the main reasons affecting the growth of high-temperature oxide scale on steel balls. Due to the differentiation effect between the oxide film and water vapor interface, the growth of oxide scale is accelerated.

4. Water vapor can migrate from the oxide film to the oxide layer through the use of small pores.

Water vapor is inevitable in high-temperature environments, and its long-term erosion by water vapor can affect its service life. To avoid such scenarios, it is necessary to improve skills and ensure application quality. When used with appropriate equipment, steel shot is an ideal abrasive for shaping the appearance due to its durability. It has the advantages of moderate hardness, strong durability, impact resistance, reusability, long service life, good rebound, strong adhesion, fast precision machining speed, low sand consumption, no breakage, high brightness of finished workpieces, and good technical effects. The cleanliness of the processed metal appearance of this product meets international standards. The surface roughness is between 25 and 150m, which increases the contact surface of the metal surface and improves the adhesion of the corroded surface. Steel shot has significant economic benefits in refining metal surfaces and strengthening metal structures, making it an ideal material for precision machining, spraying, rust removal, and strengthening.

Editor: Chihiro

1. Due to the fact that substances rich in water vapor can dissolve in oxide crystals, the oxidation kinetics will be affected when water vapor appears.

2. When steel balls are rich in water vapor, water vapor accelerates high-temperature oxidation.

3. Water vapor is still one of the main reasons affecting the growth of high-temperature oxide scale on steel balls. Due to the differentiation effect between the oxide film and water vapor interface, the growth of oxide scale is accelerated.

4. Water vapor can migrate from the oxide film to the oxide layer through the use of small pores.

Water vapor is inevitable in high-temperature environments, and its long-term erosion by water vapor can affect its service life. To avoid such scenarios, it is necessary to improve skills and ensure application quality. When used with appropriate equipment, steel shot is an ideal abrasive for shaping the appearance due to its durability. It has the advantages of moderate hardness, strong durability, impact resistance, reusability, long service life, good rebound, strong adhesion, fast precision machining speed, low sand consumption, no breakage, high brightness of finished workpieces, and good technical effects. The cleanliness of the processed metal appearance of this product meets international standards. The surface roughness is between 25 and 150m, which increases the contact surface of the metal surface and improves the adhesion of the corroded surface. Steel shot has significant economic benefits in refining metal surfaces and strengthening metal structures, making it an ideal material for precision machining, spraying, rust removal, and strengthening.

Editor: Chihiro

steel shot Relevant information

steel shot Related Products

- E-mail zs@sdsmachinery.com

- whatsapp +8615653328535

- Wechat +8615965331535

-

Shandong Metal Abrasive Co., Ltd produces China steel shot and alloy steel shot at a low price, with a complete range of models and a professional team