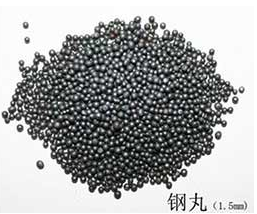

What are the requirements for cutting alloy steel shots

The quality of alloy steel shot cutting is the key to determining its usage quality. So many times, operators pay special attention to this operation step and need to follow the correct requirements for operation. Otherwise, not only will the usage effect be poor, but the quality and service life will also be reduced, which is not worth the loss. Then, in order to help everyone better understand, the editor will carefully analyze the requirements for alloy steel shot cutting.

1. Alloy steel shot cutting should release actual samples and reserve welding shrinkage allowance and machining allowance for manufacturing and installation according to process requirements.

2. Straightness and straightness exceeding tolerances should be corrected first before cutting.

3. If materials need to be received, the entire board needs to be connected, and submerged arc welding is used for automatic welding. After passing the non-destructive testing, alloy steel shot marking and cutting production are carried out.

4. The groove weld between it and the beam, and the level weld between the beam, column plate, and end plate.

During the process of cutting alloy steel balls, it is important to pay attention to the strength of the material being cut. skill comes from practice. Through long-term work accumulation and operational experience, we will be better at cutting materials. Therefore, before mastering it, we need to operate carefully and meticulously according to the prescribed method standards.

Editor: Lena

Alloy steel shot Relevant information

Alloy steel shot Related Products

- E-mail zs@sdsmachinery.com

- whatsapp +8615653328535

- Wechat +8615965331535

-

Shandong Metal Abrasive Co., Ltd produces China steel shot and alloy steel shot at a low price, with a complete range of models and a professional team